- No.99 Panlong Mountain Road, Chengdong Street, Jiangyin City, Jiangsu Province

- +86-510-86992991

- +86-510-86997008

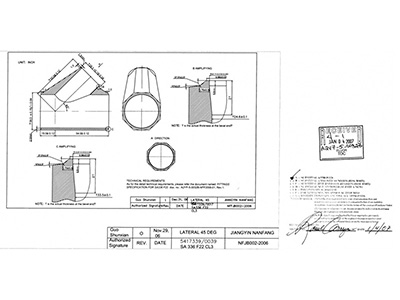

In 2007, we customized a forged 45 degrees lateral tee for a thermal power plant in USA. It featured a size of NPS 38×NPS 28, material of ASME SA336 F22 CL3, net weight of 8 ton. This heavy duty tee is the heaviest pipe fitting we have produced so far.

In 2007, NFF provided a custom long radius 90 degrees elbow for a thermal power plant in USA. Its outer diameter was 660mm, thickness was 139.7mm and material was ASTM A234 WP22. This thick walled pipe elbow is the thickest pipe fitting we have produced so far, which was made by 160mm thick seamless steel pipe underwent hot forming.

Reducing barred tees were used in a natural gas piping system in Mexico in 2015. Its dimension was NPS 42×16 / 0.812″×0.312″ and material was WPHY-70.

The reducing tee was formed by steel plates through roll welding and hot pressing. After heat treatment, bars were welded on branch outlet. Radiographic testing was conducted to inspect the quality of welds.

NFF is a qualified supplier of Shell. We provided carbon steel, stainless steel and low temperature carbon steel elbows, tees, reducers, end caps and other pipe fittings for one of Shell’s projects in Saudi Arabia in 2018.

NFF has been offering pipe fittings and flanges for a petroleum chemical fertilizer project in Brazil since 2013, including carbon steel, alloy and stainless steel pipe fittings. By virtue of 30 years of manufacturing experience and strict quality control, NFF has become the long-term supplier of this project.

In 2013, due to the rich manufacturing experience of forged pipe fittings and excellent product quality, NFF was chosen to supply forged pipe fittings and flanges for an EPC-LS Project of alumina refinery in Saudi Arabia.

From 2009 to 2012, NFF had provided industrial pipe fittings and flanges for Oyu Tolgoi mine, an auricupride project in Mongolia.

American Charles Chemical Project included a 1.5 million tons/year C2H6 splitting decomposition device and six downstream chemical manufacturing facilities. NFF had provided this project with stainless steel elbows, tees, reducers, flanges, etc. from 2015 to 2017. The contract was worth $3.5 million.

Project: shipyard

Region: South Korea

Time: 2007

Product: carbon steel pipe fittings

Project: power plant

Region: Iraq

Time: 2005

Product: alloy pipe fittings

Project: natural gas pipelines

Region: Bangladesh

Time: 2002

Product: carbon steel and alloy pipe fittings

Project: paper making factory

Region: Brazil

Time: 2012

Product: stainless steel pipe fittings

Project: Coal tar filter design, procurement and construction management project

Region: South Africa

Time: 2014

Product: tees, elbows, end caps, reducers, flanges, etc.

Project: Sakhalin project

Region: Russia

Time: 2018

Product: low temperature carbon steel and stainless steel elbows, tees, reducers, end caps, etc.

Project: petroleum transport pipeline

Region: Dubai

Time: 2012

Product: carbon steel and stainless steel pipe fittings including reducers, elbows, tees, weldolets and more.

Project: mining project

Region: Dominican Republic

Time: 2012-2013

Product: pipe fittings and flanges

Project: power station

Region: Argentina

Time: 2015

Product: alloy steel pipe fittings